|

|

|

NEW RELIC: Jin Jin, sixth-generation inheritor of the brick manufacturing technique, introduces an imitation of ancient bricks for collection purposes |

Smooth and shiny "golden bricks" have been used to build imperial palaces since the Ming and Qing dynasties (1368-1911). They are a specialty of Lumu, a town near Yangcheng Lake in Suzhou City, east China's Jiangsu Province.

The bricks got their name from the tedious manufacturing process and the high costs involved, and for their incredible durability to stand the test of time just like gold, which never corrodes or loses its luster. The bricks can still be seen today in the Hall of Supreme Harmony in Beijing's Forbidden City, also known as the Palace Museum .

The manufacturing process is very complicated and requires 29 procedures, including selecting pure clay from the lake, then shaping, drying, firing and polishing. The rate of production is very low, thus "one brick, one liang (50g) of gold."

The Ming Dynasty (1368-1644) emperor Yong Le (1403-1424) named Lumu an imperial kiln for its strict firing procedures and high-quality product. The Lumu brickmaking technique was named a State Intangible Cultural Heritage in 2006.

Renovation and repairs of the Forbidden City, Temple of Heaven and other ancient architecture in Beijing use Lumu's bricks exclusively.

Currently, 20 craftsmen fire the only remaining kiln in Lumu. The long production period, tedious labor, the high cost and low benefits have put the gold brick business on the verge of extinction.

According to Jin Jin, a sixth-generation inheritor of the manufacturing technique, the factory has developed bricks for calligraphy exercises and pseudo-classic bricks.

Jin's heritage project makes bricks which are exact replicas of those produced by the imperial kiln 600 years ago to celebrate the hexacentennial of the Forbidden City and the 600th anniversary of the kiln's imperial designation in 2019.

Brazil, Russia, India, and South Africa--the other four BRICS countries--will exhibit Lumu's imperial bricks in October this year.

|

|

MIXING CLAY: A brickmaker presses clay into a die |

|

|

SHAPING UP: A brickmaker levels an unfired brick |

|

|

FUELS: Combining wood bits and rice shells for fuel is essential. The imperial kiln consumes 2.5 tons of such fuel each day |

|

|

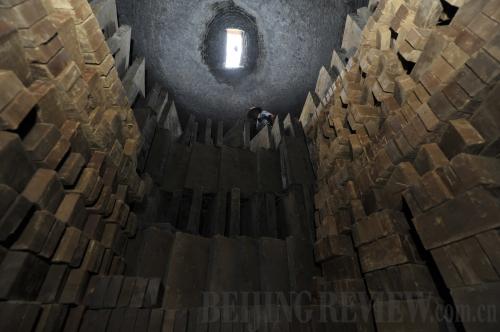

INSIDE THE KILN: Bricks are placed inside the ancient kiln to bake |

|

|

HEAT ADJUSTMENT: A brickmaker cleans ashes inside the kiln to adjust the firing duration. Brickmakers make adjustments to temperature around the clock during four months of firing |

|

|

MOVING BRICKS: Lumu brickmakers move nearly finished bricks |

(Source: Xinhua and China Cultural Daily) |