| China |

| Fujian's businesses are thriving through hi-tech upgrading | |

|

|

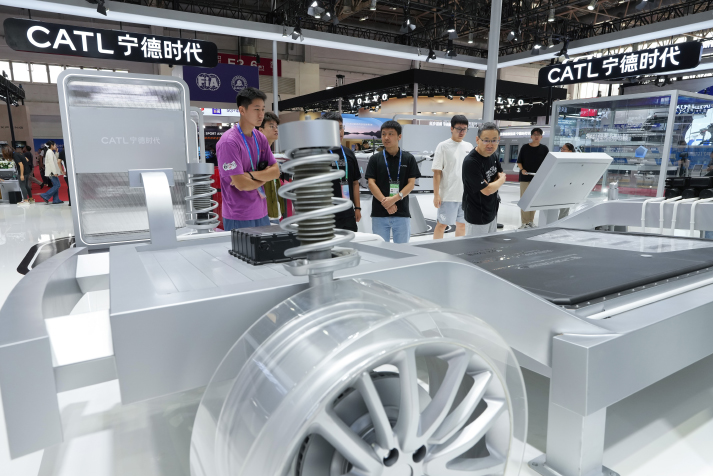

The super batteries of Contemporary Amperex Technology Co. Ltd.(CATL) are on display at the third China International Supply Chain Expo in Beijing, capital of China, July 19 (XINHUA)

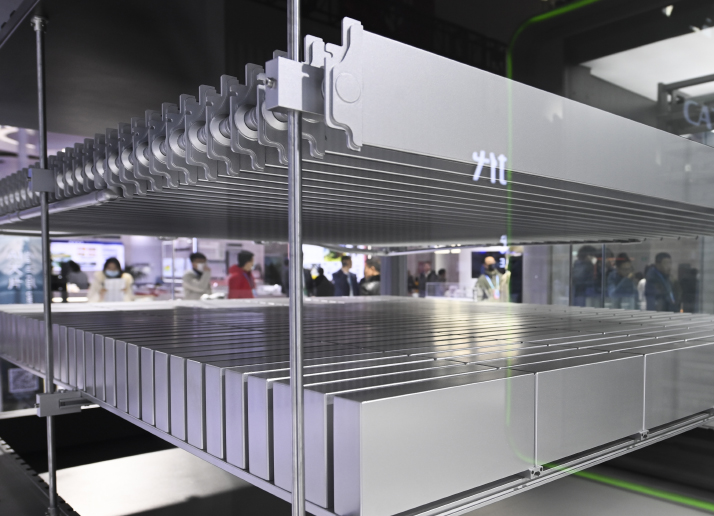

CATL, or Contemporary Amperex Technology Co. Ltd., began its life in 2011 as an obscure power battery startup facing multiple technological bottlenecks and fierce competition. Today, it produces a third of the world's electric car batteries and supplies 16 of the world's biggest carmakers, including General Motors, the Shanghai factory of Tesla, BMW, Toyota and Volkswagen. Headquartered in Ningde in the northeast of Fujian Province, CATL has operations covering the entire electric car battery production chain, from materials to finished products. Its breakthroughs in high energy density, ultra‑fast charging and battery stability have greatly reduced consumers' concerns about electric vehicle (EV) range, charging times and safety; and accelerated the pace of global electrification. The company has taken the economic output of Ningde to new levels. Only a decade ago, Ningde's GDP was the lowest in the province; but in the first half of 2025, its GDP hit 193 billion yuan ($28 billion), ranking the fifth out of Fujian's nine cities.  Kirin batteries manufactured by CATL, or Contemporary Amperex Technology Co. Ltd., in Ningde City, Fujian Province, December 1, 2023 (XINHUA)

In search of excellence CATL has continuously innovated its cutting-edge battery products and technologies in recent years, breaking many of its own previous records. So far, the company has more than 40,000 patents granted or pending. Batteries constitute at least a third of the production cost of an EV, making CATL a critical partner in the EV supply chain in China and beyond. According to rechargeable battery and EV research firm SNE Research, in 2024, CATL accounted for 37.9 percent of the global market in power battery usage and 36.5 percent in the global energy storage battery market. Lithium-ion batteries are divided into consumer batteries, used in consumer electronics; power batteries, used in vehicles and power tools; and energy storage batteries used in energy supply or to power facilities. As of this June, the company's batteries had powered more than 20.43 million vehicles in 66 countries and regions worldwide. In addition, the company also supplies grid energy storage systems to domestic and overseas markets. On January 17, Emirati renewable energy company Masdar announced CATL is the preferred provider of battery energy storage systems for the world's first giga-scale "round-the-clock" photovoltaic energy storage project, set to be built in Abu Dhabi. In 2022, CATL launched its third-generation cell-to-pack (CTP) battery technology, known as Kirin or Qilin. Compared with traditional batteries, CTP batteries are easier, faster and cheaper to produce and enable an EV to travel up to 1,000 km on a single charge. In July 2024, CATL launched two products for the logistics and distribution industry, the superfast charging edition and long-range edition of the CATL Tianxing light commercial vehicle battery. One adds 200 km of range in just 10 minutes and the other delivers a full-charge range that meets a day's long-haul delivery needs. In April, the company unveiled a battery that will provide a driving range of 520 km with five minutes of charging. This second‑generation Shenxing ultra-fast charging battery is the world's first lithium‑iron‑phosphate battery that reaches a peak 12 C-rate, with an 800‑km range. C-rate refers to the rate at which a battery charges or discharges relative to its maximum capacity. The higher the C-rate, the faster charging or discharging occurs. Also in April, it launched the CATL Freevoy dual power battery. Each battery pack is divided into two independent energy zones, or high‑voltage systems, effectively giving the vehicle a dual‑engine configuration. Even if one side is damaged in an extreme collision, the other side can take over seamlessly in a matter of milliseconds. On June 10, CATL announced that it has started the mass production of its next-generation, high-capacity energy storage cell—the 587Ah cell, which enables a 25-percent gain in overall system energy density. In December, CATL will begin selling sodium-ion batteries, which can retain over 90 percent of their charge at temperatures down to minus 40 degrees Celcius, for use in hybrid cars and trucks. In addition to power batteries and energy storage batteries, CATL also provides batteries for emerging sectors such as construction machinery, aircraft, marine vessels and robotics. These sectors have much higher requirements for battery quality and safety than the EV industry. These innovations have been made on the back of robust research and development (R&D) investment, with CATL's financial statements showing that, from its 2018 initial public offering on the Shenzhen Stock Exchange to today, its total R&D investment has surpassed 80 billion yuan ($11 billion). "Our pursuit of extreme product performance and rigorous quality standards throughout the whole production process underpins our global ambitions," Wu Zhenhua, CATL's chief engineer of passenger vehicle technology, said in a group interview on August 21. The company's development has also been spurred on by support from local government organizations. In order to foster a new energy battery industrial cluster in Ningde, the city's government offers CATL and related companies preferential policies in land use and electricity use. The companies also receive financial support from local banks, in the form of a higher line of credit and lower loan interest rates. Ningde's goal is to encourage the strongest players to play a leading role in its efforts to build an industry cluster, which lets more businesses and places get involved in the supply chain so that they can also make money. CATL's presence in Ningde has attracted more than 80 upstream and downstream enterprises, allowing leading companies like CATL to meet 80 percent of their procurement needs locally. In this way, a globally renowned lithium-ion battery new-energy industry base has been born in Ningde. Adding to this has been the large influx of talent. CATL alone has more than 20,000 R&D staff, largely in Ningde, attracted by career opportunities and high pay. Together with employees of related companies, they're helping to boost the city's innovation capacity, creating a virtuous cycle of development.  Staff members at work in a workshop of SEMS Enterprise, a footwear company in Putian, Fujian Province on August 19. The company’s intelligent production line can manufacture customized shoes in just over an hour (XINHUA) Upgrading traditional industries While hi-tech companies like CATL are developing domestically and even globally, traditional industries in Fujian are also innovating and upgrading. To bring innovation to its industries across the board, government authorities in Fujian issued a three-year plan for digital transformation in 2022, encouraging businesses to take advantage of advanced science and technologies. A growing number of businesses have increased their R&D input in recent years, with AI technology taking up a large share. The upgrading of traditional industries not only helps increase the added value of products, but also helps enhance their competitiveness, sparing them from the fate of becoming OEMs (original equipment manufacturers), on businesses that manufacture on behalf of others. Businesses in Putian City in the east of the province have been manufacturing shoes for famous international brands like Nike, Decathlon and Adidas since the 1980s. The city is now home to more than 4,000 shoe companies, which employ about 500,000 people and create an output value of more than 100 billion yuan ($14 billion) a year. For many years, despite the high quality of their shoes, shoe businesses have long struggled to establish well‑recognized independent brands, which leaves them at a persistent disadvantage within the value chain. "Our strategy is to leverage digital technology to enable customization," said Chen Qixian, chief expert at the Putian Footwear Association, in a group interview on August 19. SEMS Enterprise, founded in 1991, is an established name in the Chinese sports shoe industry. It has developed, in partnership with the Chinese Academy of Sciences, Footbird, a foot posture scanner that can scan a foot and capture detailed data about foot shape, pressure and posture within 15 seconds, and uses AI technology to recommend the best shoe style and size for each customer. This technology has made SEMS a shoe-customization smart factory. "People's foot shapes differ. Even if the size is the same, slipping into someone else's shoes still makes one feel uncomfortable. That is what drives SEMS to make custom-fit footwear," said Gu Weiming, general manager of the customization program. "Our current shoe models cover more than 500 sub-types and sizes. Once an order is placed, it goes to the central order system, which automatically directs production across different lines. It takes as little as two hours to make a pair of customized shoes," said Gu. A striking advantage of customized sportswear is that the company has very low or zero inventory. As inventory usually erodes a large portion of profits, large-scale smart manufacturing enabled by digitalization helps significantly reduce the company's costs. In 2024, SEMS' revenues hit around 1.5 billion yuan ($211 million), according to Gu. In recent years, inspired by SEMS' successful example of customization and smart manufacturing, many shoe companies in Putian have transformed from OEM production to the creation of independent brands, thanks to their own independent innovations in technology, materials, design and other areas. At the same time, a series of local shoe brands have emerged, like Fanthuat, Erke, GuiRenNiao and Peak.  Tea is aired in Daping Village, Fuding City of Fujian Province on April 10, 2024. Fuding boasts a big white tea industry (XINHUA)

The hi-tech and digital transformation sweeping Fujian is not only influencing emerging industries and decades-old industries like footware manufacturing, but is reshaping a centuries-old industry—the white tea industry—as well. White tea is one of China's six traditional tea categories. Fuding City in northeast Fujian has been producing white tea for 1,400 years and is known as the hometown of white tea in China. In 2024, 380,000 people in the city were involved in business related to white tea and the total economic output of its white tea industry stood at about 15 billion yuan ($2.1 billion). Fujian Pin Pin Xiang Tea Industry Co. Ltd., established in 1992, has established a white tea refining production line. Taking the tea through a six-step refining process, the hands-free production line completes the work that otherwise requires 50 skilled employees. After tea leaves pass through this line, only 75 percent of the white tea will remain. The other 25 percent undergoes deeper processing and extraction for incorporation into products such as hand creams and toiletries, according to Li Caiping, executive director of Pin Pin Xiang. Pursuing high-quality production and value adding has allowed Pin Pin Xiang to maintain its business despite sluggish tea consumption in China in recent years. The company is just one of the white tea producers in the region that have taken these measures to maintain their viability. To ensure the quality and safety of white tea, all tea gardens in Fuding are pesticide-free. A big data-based platform that tracks the entire supply chain—from tea garden to tea cup—was launched in 2019. Technologies such as satellite remote sensing and drone mapping are used to collect data from the 24,012 hectares of white tea gardens and 3,137 processing entities. As a result, consumers can see every step of the tea's journey, from planting to processing, by simply scanning a QR code. By 2024, the system had intercepted 120 tons of subpar tea leaves, helping ensure product quality. The massive data collected also inform the local government's formulation of industry policies and tea producers' planning and management. In addition to enhancing production efficiency and product quality with advanced automation as well as smart operations, Fuding's villages have integrated tea growing and processing with tourism to promote rural revitalization. Chixi Village in Fuding is said to have triggered a nationwide poverty reduction campaign after its poverty was reported by newspaper People's Daily in 1984. The village has now benefited from the upgraded tea industry and rural tourism. It is now home to 12 white tea companies and six cooperatives. In 2024, the per-capita disposable income of the village's residents hit 39,487 yuan ($5,546)—or 1.7 times the national average for rural residents—with more than 40 percent of the income coming from white tea. As a pillar industry in Fuding, white tea is not only improving livelihoods, but also presenting the Chinese tea and tea culture to the wider world. In 2024, Fuding exported 1,200 tons of white tea to Europe, the United States, Southeast Asia and other regions, with dedicated Fuding white tea stores in Germany and France. In May, the Fuding White Tea Culture System was designated by the United Nations Food and Agriculture Organization as a Globally Important Agricultural Heritage System. (Reporting from Fujian Province) Copyedited by G.P. Wilson Comments to panxiaoqiao@cicgamericas.com |

|

||||||||||||||||||||||||||||

|